Description

Main feature

-Composite structure of main display unit ,driver unit and Sensor.Electromechanical integration design, small size, light weight, easy to operation;

-Support Bluetooth printing and mobile APP wireless operation.

-Multiparameters:Ra,Rz,Rq,Rt,Rp,Rv,R3z,R3y,Rz(JIS),Rs,Rsk,Rsm,Rku,Rc,Ry,Rmax,Rmr; RPc、Rk、Rpk、Rvk、Mr1、Mr2

-In addition to calculation results, the tester can display primary profiles and assessed roughness profiles and load curves.

-320µm Large measurement range;

-The 3.5-inch color graphic LCD provides excellent readability and an intuitive display that is easy to negotiate. The LCD of 480*320 dot matrix includes a adjustable backlight for improved -visibility in dark environments. Wide angle of view;

-DSP chip control and data processing, high speed, low power consumption;

-Display full information, intuitive and graphical displays all parameters;

-The tester Complies with the following standards: ISO4287,ANSI b46.1,DIN4768,JISb601

-4 Profile Filter: Gauss RC PC-RC D-P

-Built-in 3000mAh lithium-ion rechargeable battery and control circuit, high capacity, no memory effect;

-The tester can graphically display the remaining battery power.

-The tester can be animated to show that it is charging and filling., the operator can readily understand the level of charge

-Can work more than 50 hours while the power is enough;

-Large capacity data storage, can store 100 item of raw data and measured profile;

-Real-time clock setting and display for easy data recording and storage;

-With automatic sleep, automatic shutdown power-saving features;

-Reliable circuit and software design of prevent the motor stuck;

-Instrument can display a variety of information tips and instructions. For example Measurement result display, the menu prompts and error messages;

-Can connected to the computer and printer;

-All parameters can be printed or print any of the parameters which set by the user;

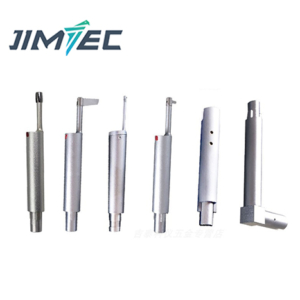

-Optional curved surface pickup sensor, holes sensor, minuteness holes sensor, measurement stand, Sheath of sensor, extension rod, printer and analysis software;

Technical Parameters

| Name | Content | |||

| Measurement Range | The Z axis (vertical) | 320µm (-160µm~160µm) / 12600μin (-6300μin~+6300μin) | ||

| The X axis (horizontal) | 17.5mm/0.69″ | |||

| Resolution ratio | The Z axis (vertical) | 0.002μm/±20μm | 0.004μm/±40μm | |

| 0.008μm/±80μm | 0.02μm/±160μm | |||

| Measurement item | Parameter | Ra Rz Rq Rt Rc Rp Rv R3z R3y Rz(JIS) Ry

Rs Rsk Rku Rmax Rsm Rmr RPc Rk Rpk Rvk Mr1 Mr2 |

||

| Standard | ISO4287,ANSI b46.1,DIN4768,JISb601 | |||

| Graphic | Primary profile, Roughness profile, load curves | |||

| Filter | RC,PC-RC,Gauss,D-P | |||

| LCD dimensions | 3.5-inch 480*320 | |||

| The sampling length(lr) | 0.25,0.8,2.5mm | |||

| Assessment length(ln) | Ln= lr×n n=1~5 | |||

| Sensor | Principle | The displacement differential inductance | ||

| Stylus | Natural Diamond, 90B cone angle, 5µm tip radius | |||

| Force | <4mN | |||

| Skid | Ruby,Longitudinal radius 40mm | |||

| Traversing speed | lr=0.25, Vt=0.135mm/s | |||

| lr=0.8, Vt=0. 5mm/s | ||||

| lr=2. 5, Vt=1mm/s | ||||

| Return, Vt=1mm/s | ||||

| Accuracy | ±(5nm+0.1A) A: Ra of calibration test block | |||

| Repeatability | No more than 3% | |||

| Power supply | Built-in3.7VLithium ion battery,Charger :DC5V,800mA/3hour | |||

| Working Time | More than 50 hours | |||

| Size( L*W*H) | Display Unit | 158*55*52mm | ||

| Drive Unit | 115*23*27mm | |||

| Weight | About 400g | |||

| Working Environment | Temperature:- 20℃ ~ 40℃

Humidity:< 90% RH |

|||

| Store and Transportation | Temperature:- 40℃ ~60℃

Humidity:< 90% RH |

|||

Standard Configuration

| Number | Name | Quantity | Remarks |

| 1 | Main Unit | 1 | |

| 2 | Sensor | 1 | Precision parts |

| 3 | Adjustable height support feet | 1 | |

| 4 | Calibration block | 1 | |

| 5 | Block bracket | 1 | |

| 6 | Extension cable | 1 | |

| 7 | Touch pen | 1 | |

| 8 | Charger | 1 | |

| 9 | USB charging cable | 1 | |

| 10 | Operating manual | 1 | |

| 11 | Certificate | 1 | |

| 12 | Guarantee card | 1 | |

| 13 | Instrument container |

Optional configuration

| JITAI55 | -Extension rod. Used to extend length of sensor when testing deep hole (55mm) |

| JITAI90 | –Right angle measuring mechanism. |

| JITAI100 | –standard sensor, plane & shaft & inner surface of hole>6mm, depth <22mm |

| JITAI120 | –small hole sensor, cylindrical& plane &inner surface of hole>2 mm, depth <9mm |

| JITAI110 | –sensor for curved surface & plane, cylindrical, curvature radius>3 mm |

| JITAI131 | –sensor for deep groove, cylindrical & plane & groove width>3 mm, depth<10mm |

| JITAI520 | -Metal(Al)working platform, elevating, convenient and stable for test process. |

| JITAI620 | -Marble substrate working platform, elevating, V groove, high accuracy to test tiny work piece. |

| Roughness comparison block |

High quality comparison block of surface roughness Strict anti-rust treatment process 27 comparison block/set |

| Mini Pinter |

External printer |

Reviews

There are no reviews yet.