Description

Introduction

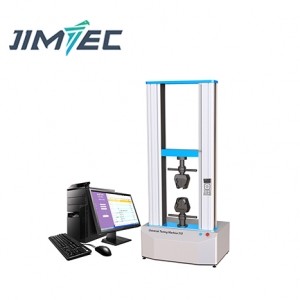

The microcomputer control electronic universal testing machine started in the early 1990s, in order to improve the technical level of enterprise products, the company has introduced foreign advanced technology, so that the company’s product technical level jumped to a new level. This test measurement and control system is designed for electronic universal testing machine matching set measurement, control in one of the measurement and control instrument. Can be tensile, compression, bending, shear, tear, peel and other tests.

The system adopts the world’s most advanced 32-bit ARM technology, with 24-bit high-precision AD and large memory capacity, with high measurement accuracy, rapid and stable response, fast and accurate control speed. Dot matrix graphic LCD is used to display, save and print the test results in the form of direct text and graphics (optional miniature thermal printer). User operation using Chinese characters display multi-layer menu structure, powerful, easy to operate, and added to the operation of fault tolerant processing and automatic fault search, prompt function, such as sensor, AD value, unit, zero, calibration value; Range, rated deformation, calibration value; And whether to automatically start the test, automatically judge the crack, automatically return to the starting point and other parameters. The maximum force, yield force, average peeling force, maximum deformation and other test parameters can be calculated.

The Field of Use

Microcomputer control material testing machine for plastic, film, textiles, rubber, plastic, fiber, nanometer materials, polymer materials, composite materials, packaging, paper, wire and cable, fiber optic cable, seat belts, belts, leather belt, shoes, belt, polymer, spring steel, bearing steel, stainless steel, and other high hardness steel), castings, steel plates, steel, non-ferrous metals , auto parts, alloy materials and other non-metallic materials and metal materials for tensile, compression, bending, tearing, 90° peel, 180° peel, shear, adhesive force, pull out force, elongation and other tests.

Feature

1.Host machine: This machine adopts single-arm structure, lower space compression, beam stepless lifting. Transmission part adopts circular arc synchronous tooth belt, lead screw pair transmission, stable transmission, low noise. The specially designed synchronous gear belt deceleration system and precision ball screw pair drive the moving beam of the testing machine to realize the non-clearance transmission.

2.Accessories:

Standard configuration: one standard fixture (can be selected according to customer requirements).

3.Electrical measurement and control system:

(1) AC driver and AC motor, stable and reliable performance, with over-current, over-voltage, overspeed, overload protection devices. Speed regulation ratio can reach 1:100000.

(2) With overload, over current, over pressure, displacement limit and emergency stop and other protection functions.

(3) Built-in controller to ensure that the testing machine can achieve test force, sample deformation and beam displacement and other parameters of closed-loop control, can achieve constant speed test force, constant speed displacement, constant speed strain, constant speed load cycle, constant speed deformation cycle and other tests. The various control modes can be smoothly switched between.

(4) At the end of the test, it can return to the initial position of the test at high speed manually or automatically.

(5) Realize the real sense of physical zero adjustment, gain adjustment and test force measurement of automatic shift, zero adjustment, calibration and storage, without any analog adjustment link, the control circuit is highly integrated.

(6) the electrical control line with international standards, in line with the national testing machine electrical standards, strong anti-interference ability, to ensure the stability of the controller, the accuracy of experimental data.

Electronic universal material testing machine can be tested items

(I) Common test items :(ordinary display value and calculated value)

- Tensile stress ● Tensile strength

- Tearing strength ● Tearing elongation

- Constant stress ● Constant stress elongation

- Fixed stress and force ● Tearing strength

- Force value at any point ● Elongation at any point

- Extraction force ● Adhesive force and take the peak value to calculate

(2) Special test items:

- The elastic coefficient is the elastic Young’s modulus

Definition: the ratio of the normal stress component to the normal strain in the same phase. Is the coefficient of rigidity of a material, the higher the value, the stronger the material.

- Proportional limit: the load can be maintained in a proportional relationship with the elongation within a certain range, the maximum stress is the ratio limit.

- Elasticity limit: the maximum stress that a material can bear without permanent deformation.

Technical Parameters

Test machine level: 0.5 level

Test force index:

Maximum value: 50kN

Measuring range: 0.2%-100%

Accuracy: better than ± 0.5% of the indicated value

Resolution: ±300000 yards

Deformation index: optional

Maximum value: 10mm

Measuring range: 2%-100%

Accuracy: better than ± 0.5% of the indicated value

The displacement:

Measuring accuracy: better than ± 0.5% of the indicated value

Resolution: 0.001mm

Speed:Range: 0.005mm/min ~ 500mm/min stepless speed regulation,Accuracy: better than ± 1% of the indicated value

Host parameters:Tensile stroke: 780mm,Compression stroke: 1000mm,Test width: 410mm

Working environment: room temperature 10 ~35℃, humidity 20% ~ 80%

Force control rate adjustment range: 0.005– 5%FS/S;

Force control rate control precision: when the rate is < 0.05%FS, it is within ±1% set value; Rate >0.05%Fs, it iswithin ±0.5% set value.

10.deformation rate adjustment range: 0.02-5%FS/S;

Accuracy of deformation rate control: when the rate is < 0.05%FS, it is within ±1% set value; Rate >0.05%Fs,it iswithin ±0.5% set value.

Accuracy of displacement rate control: when the rate is < 0.01mm/min, it is within ±1% of the set value; When the speed is > 0.05mm/min, it is within ±0.2% set value.

Constant force, constant displacement, constant deformation control range: 0.5%~100% FS

constant force, constant displacement, constant deformation control accuracy: when the set value is ≥ 10%FS, it is within ±0.1% of the set value; When the speed rate is < 10%FS, it is ±1% of the set value

host size: about 860*550*1900 mm(length * width * height)

Software Introduction

Software comes with test standards, including GB, ASTM, BIS, ISO, JGB, JIS, BS, such as test standard.

It includes stretching, compression, bending, stripping, tearing, shearing and other test methods.

Let customers in the use of direct call, more convenient, intuitive

Software comes with test standards, including GB, ASTM, BIS, ISO, JGB, JIS, BS, such as test standard.

It includes stretching, compression, bending, stripping, tearing, shearing and other test methods.

Let customers in the use of direct call, more convenient, intuitive.

System Configuration

| No | Name | Manufacturers and specifications | QTY | Note |

| 1 | Main frame | Zhejiang DANA | 1 | |

| 2 | Motor and system | Stepper motor | 1 | |

| 3 | Ball screw | Zhejiang DANA | 1 | |

| 4 | Load cell | 50KN | ||

| 5 | Work fixture | standard fixture | 1 | |

| 6 | Software | Tester standard version | 1 | |

| 7 | Computer | Industry computer | 1 | |

| 8 | Documents | Manual, product certificate,etc | 1 |

Reviews

There are no reviews yet.